MCAD/Mathcad

DIGITEK is always doing our best to think ahead for customers

and create new value for your business.

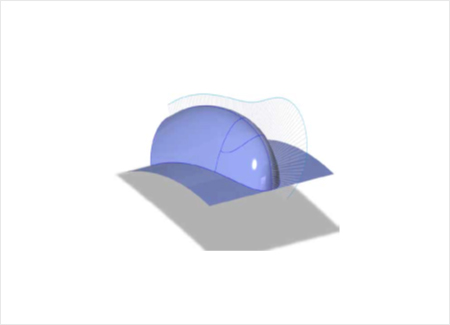

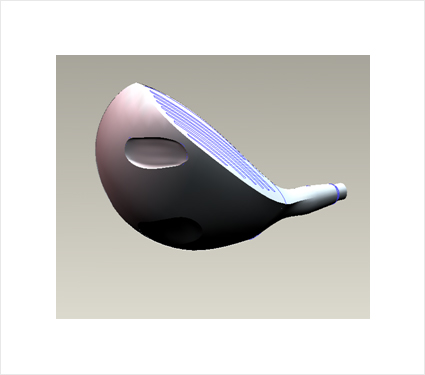

MCAD – Creo Interactive Surface Design Extension

Creates freestyle surfaces for fast and exceptional product design

PTC Creo Interactive Surface Design Extension (ISDX) truly integrates 3D design and engineering.

It combines the benefits of powerful parametric modeling and the feature for flexible creation of freestyle surfaces to create the complicated freestyle curves and surfaces all in one intuitive conversational design platform. Designers and engineers can experience powerful freestyle surface processing and this distinguished platform to use a wide variety of features all in one applied program including behavioral style modeling, systems, simulation, and manufacture proves that PTC Creo is the best product design solution.

1Features & Specifications

- Creates curves

- Edits curves

- Creates and edits surfaces

- Conversationally connects surfaces

2Benefits

- Applies the desired number of restraints to create freestyle figures at any point of design to maximize flexibility of design

- Focus on enhancing the added value of design without wasting any time on data transmission and interpretation

- Easy to learn and use for fast definition of curves and surfaces for fast ROI

- Saves product development time as any changes to the design are instantly applied to surfaces and curves through perfect correlation

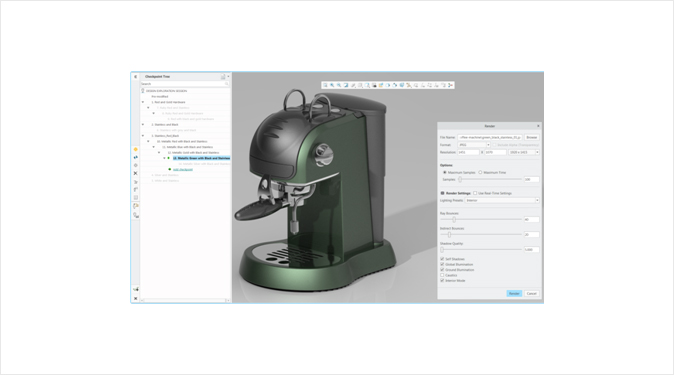

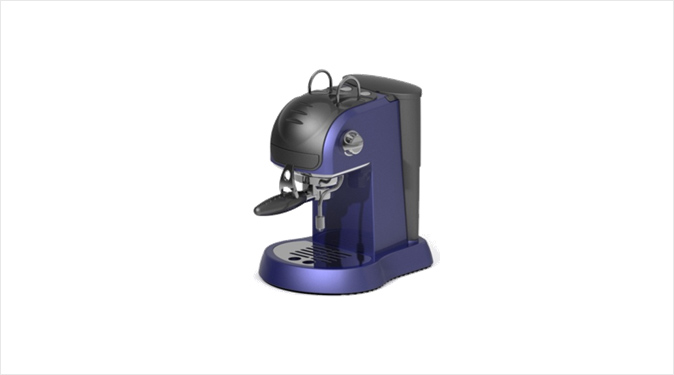

MCAD – Creo Render Studio Extension

The applied program with the simple and innovative rendering feature

With Creo Render Studio offers the Luxion’s KeyShot feature. Designers can easily create images same as those found on extremely beautiful images on photographs on Creo.

Imagine how much time and cost you can save by eliminating the process of creating desired images with elaborate light sources, scenes, and color adjustment. Creo Render Studio can also create the images just same as the images in the photographs for design review, marketing, and packaging.

Rendering is not just convenient. It also adds flexibility to operation and simplification and makes visual approaches to communication for internal/external interested parties.

1Features & Specifications

- Scenes including HDRI environment and source of light

- Premium color library for plastic, metal, and paint

- Assigns conversational materials

- Manipulates camera angle

- Exporting to share independent-action KeyShot and data

- Creates standard images such as JPEG, TIF, and PNG

- Conversational ray tracing

2Benefits

- New rendering mode

- Real-time operation

- Real-time ray-tracing

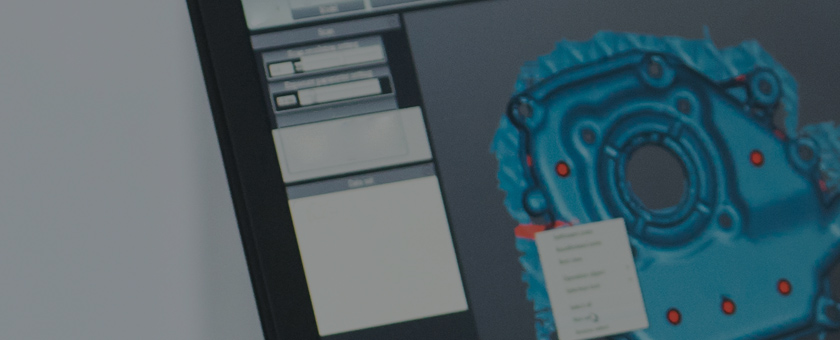

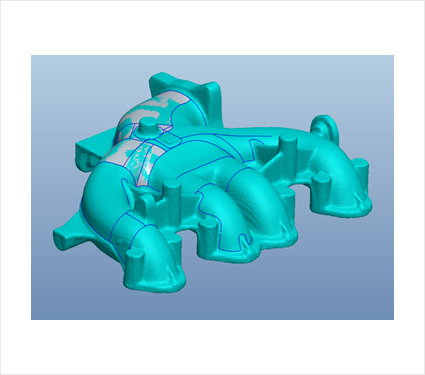

MCAD – Creo Reverse Engineering Extension

Quickly converts existing products into 3D CAD models

With PTC Creo Reverse Engineering Extension (REX), engineers can easily make and remake electronic 3D CAD models of existing products without spending enormous time, efforts, and cost. With Creo Reverse Engineering, engineers can work with the ‘dot cloud’ data that they can acquire by scanning the actual prototype.

With Creo Reverse Engineering’s Process Edge Tool, dot cloud and polygon data can be adjusted to reduce the total number of noise and/or dots. By doing so, the processing speed can be enhanced while maintaining the same level of details and the design intentions can be preserved. Now, it is possible to create surface processing models fast. Surfaces can be projected to match the boundary surfaces created by the curves sketched on the surface data or surface processing models. Also, they can create truly analyzed figures using the figure surface options such as planes, cylinders, pushed or rotated surfaces, etc.

Once a surface has been created, the entire Creo analysis tools can be used to analyze the deviation between the surface and the surface processing data. Creo Reverse Engineering perfectly preserves the design intention as it captures the physical properties such as surface tangents.

1Features & Specifications

- Fine adjustment of dot cloud

- Dynamic surface processing modeling

- Creates flexible curves

- Creates flexible surfaces

- Verification

2Benefits

- The actual prototype’s reverse engineering process is automated to save cost and shorten the development time

- Simplifies the workflow and shortens the technical training time by using the same CAD program used to design products for their reverse engineering process

- Realizes more accurate product designs by reducing the noise of dot cloud data

- Accurately captures the original product’s design intentions to maintain the integrity of design

- Automates the manual process to convert the scanned data into a manufacturable surface

- Simply updates existing designs to match the new market needs even without the original digital data

- Analyzes the discrepancies between the completed model and the surface processing data to verify accuracy