IoT

DIGITEK is always doing our best to think ahead for customers

and create new value for your business.

ThingWorx

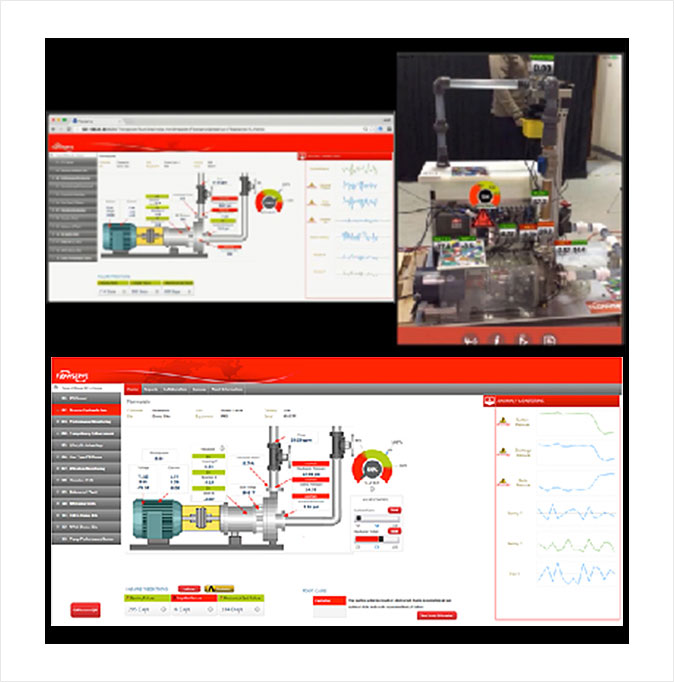

ThingWorx is an IIoT platform that provides productivity, management and analysis.

ThingWorx solves various issues that different industries commonly face ranging from remote monitoring and services to worker and asset efficiency management.

Extend application for the manufacturing industry – ThingWorx Operator Advisor

- Provides workable guideline regarding work order, machine data, and product composition within a single screen

- Can monitor real-time operation capability using various metrics of KPI(Key Performance Indicator)

Extended analysis capability

- Access FactoryTalk Analytics DataFlowML platform through ThingWorx and use machine learning

- Process optimization and improve operation efficiency through predictive model score and data set creation abilities

- Provides various analysis by adopting an external standard model PMML(Predictive Model Markup Language)

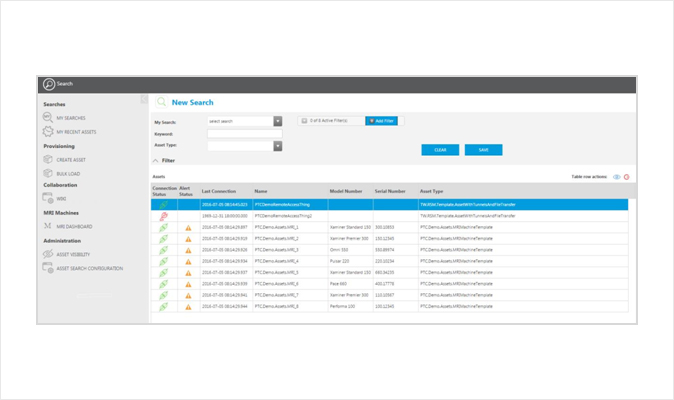

Centralized management – ThingWorx Solution Central

- Able to search, distribute and manage corporate data in general that different managers are responsible for through ThingWorx App

Hierarchy structure on asset of purchased license – ThingWorx Asset Advisor

- Supports flexible asset categorization function

- Validate business logic and visibility requirements and able to create/analyze customized workflow

Improved updates – integrated Microsoft’s Azure app and IoT Hub

- Able to directly access Azure through ThingWorx App

- Provides smooth integrated environment for ThingWorx users who uses Azure

- Supports high usability and vertical extension through connector of Microsoft Azure IoT Hub

Extended connectivity implementation option

- Offers Linux based system, and solution implementation option for small IoT gateway

Up-to-date UI Tool

- Supports unique style guide for a corporate through pre-built UI widget to abide by web standard requirements

- With new building blocks, project and widget, simplify process for creating application

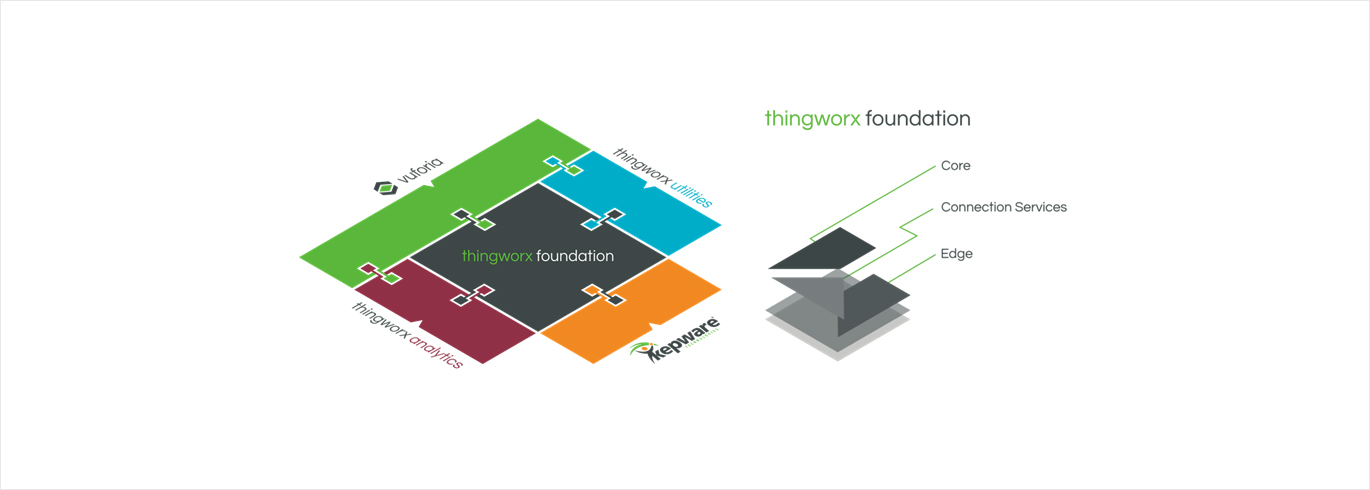

ThingWorx Foundation

Thingworx Foundation is the core of Thingworx IoT Platform.

Developers can quickly connect, create, and distribute IoT solutions for enterprises.

Thingworx Foundation provides an inclusive IoT platform and allows developers’ easy access to build and disseminate IoT solution connections.

Features of ThingWorx Foundation

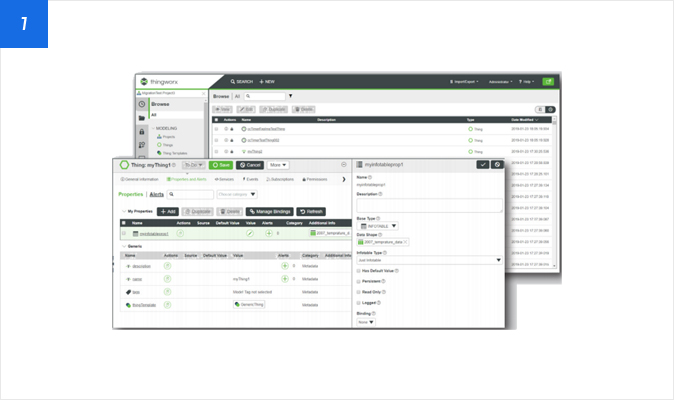

Composer

Thingworx offers an end-to-end application modeling environment for very easy modeling of “Thing”, business logic, visualization, data storage, cooperation, and security.

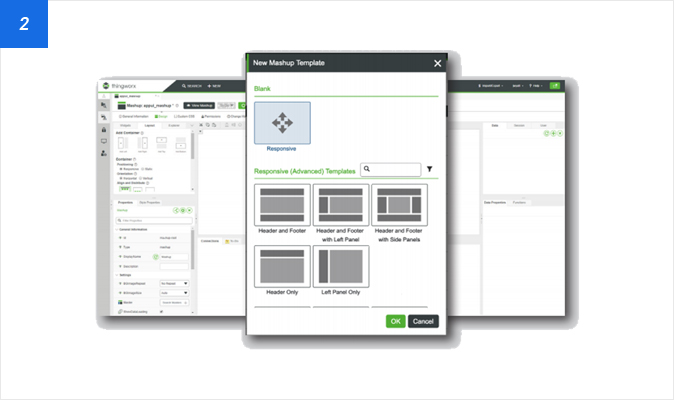

Codeless Mashup Builder

The new-generation Mashup Builder of Thingworx simplifies the complicated coding process with the ‘Drag and Drop’ interface.

Dynamic Collaboration

Thingworx virtually connects people, systems, and equipment for real-time ‘Collaborative Session’

Flexible Connectivity

Thingworx provides flexible and inclusive “connection.” Thingworx connects to devices in various ways. Kepware also allows direct connection to industrial equipment.

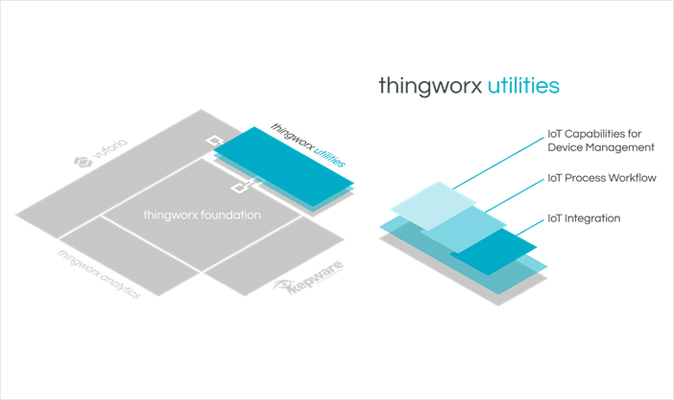

ThingWorx Utilies

The Concept of ThingWorx Utilities

Thingworx Utilities provides IoT features for device management. Business analyzers and LOB (Line-of-Business) users can easily use the features without advanced skills to manage and optimize the performance of devices. It includes pre-defined components that are easily customized and expanded by developers to build IoT applications suitable for business needs.

It includes utilities for provisioning of connected products and assets and to remotely monitor and update the software. IoT Process Workflow – Developers can create workflow for execution on various systems and the operation of connected devices begins with a warning or trigger. The workflow can be initiated by the decision-making rules.

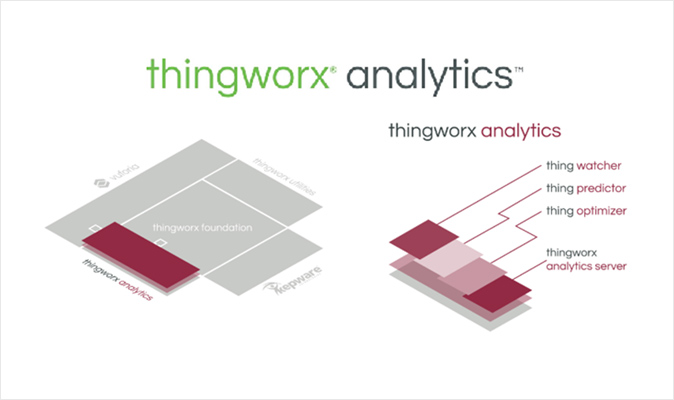

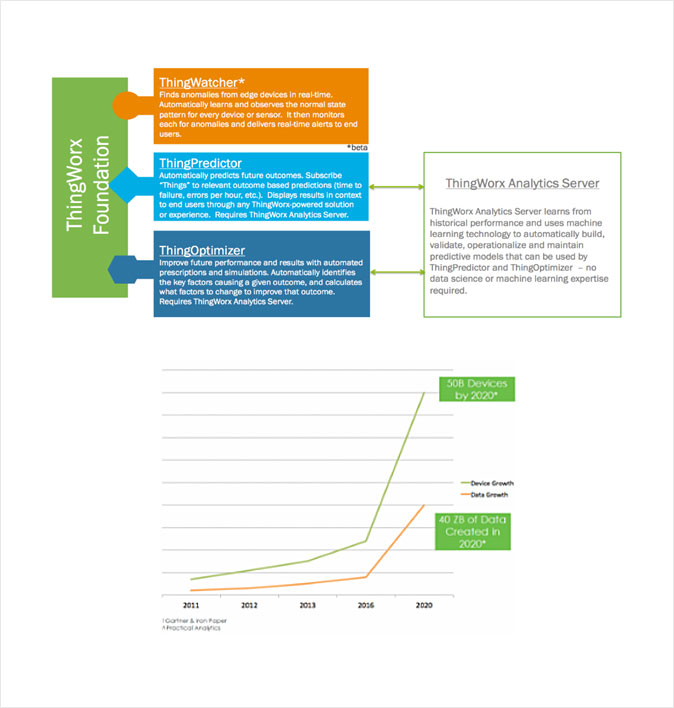

ThingWorx Analytics

The Concept of ThingWorx Analytics

- Automated IoT data applies the insights, predictions, and recommendations to the operation of department features to strengthen decision-making

- The play feature analyzes the history data and supports the forensic investigation of data in case of accidents

- The user-friendly interface converts raw industrial IoT data into applicable insights

- Longitudinal analysis detects problems in real-time to minimize the problem-solving time

The Characteristics of ThingWorx Analytics

- Provides a powerful analysis feature

- Allows analysis for preliminary response in real-time

- Provides a powerful automated analysis feature for Thingworx-based solutions

- Provides a simple user-friendly interface with easy-to-use visual tools

- Designed to be arranged at Edge, Data Center, or Cloud

-

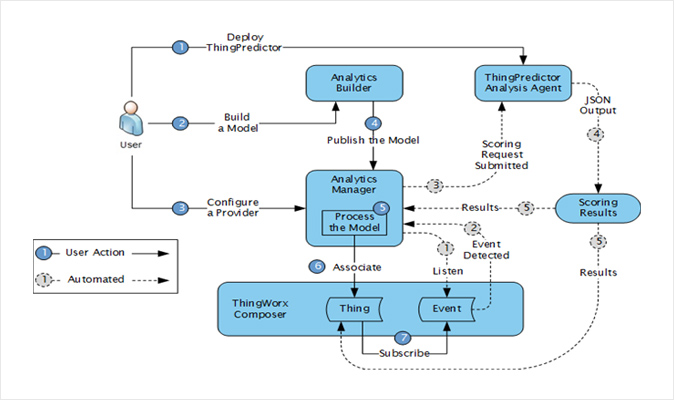

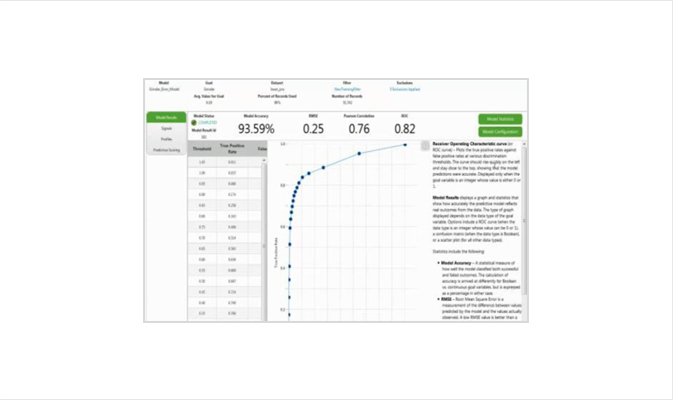

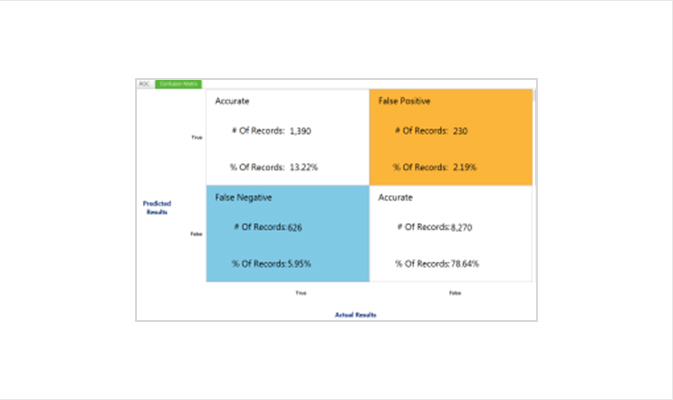

Analytics Builder

Provides simple user interface for using data and intuitive interaction. To understand complicated data analysis, convert the data into easily understandable data and simplify advanced analysis process to understand the information faster -

Analytics Manager

Use external application within ThingWorx to distribute calculated model and execute it

Able to utilize a product-based analysis model that is developed on PTC and other company’s tool -

Prescriptive Scoring and Optimization

ThingOptimizer provides Prescriptive Scoring of ThingWorx Analytics and optimization functions. Also, ThingOptimizer is able to go beyond just prediction of result and extends analysis process to shows how changes might affect the result by automatically identifying factors that might impact the result -

Predictive Modeling and Scoring

ThingPredictor provides scoring prediction function of ThingWorx Analytics.

ThingWorx Analytics Server or PMML (Predictive Model Markup Language) uses a compatible predictive model to audit data collection, and based on analyzed records and their similarities, it predicts the results of each record -

Abnomaly Detection

Without having to adopt set rules or pre-calculated formulas, it automatically monitors and learns normal status patterns, then uses this result to detect abnormality of models to score a new streaming data model and finds abnormality on a real-time basis

-

Analytics Server

Automate complicated calculation to predict, simulate and provides solution

Analytics Server, which utilizes existing and IoT data as learning resources, uses machine learning to builds and validates predictive models without support from statistics experts

Uses algorithm of a sophisticated predictive modeling to determine the most optimized algorithm for each data set and predictive subject

These prediction models can be utilized directly on ThingPredictor and ThingOptimizer to execute prediction and simulation as well as making a better decision based on the recommended guideline

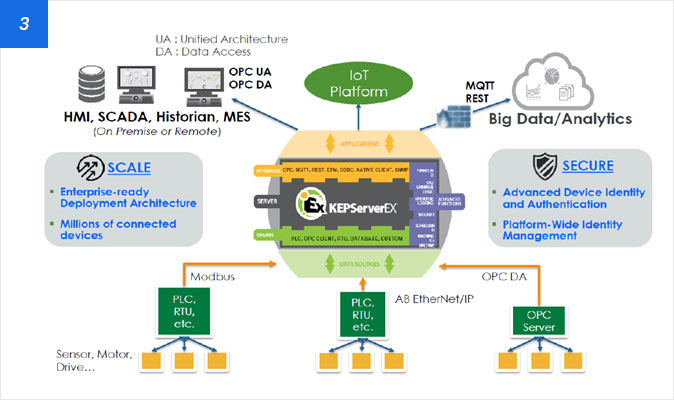

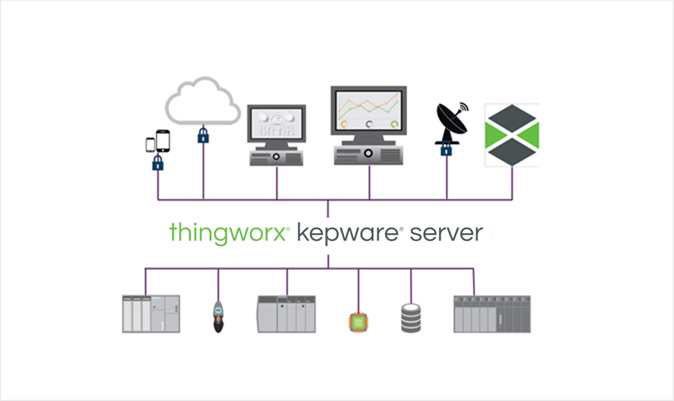

Thingworx Kepware Server

Thingworx Kepware Server

- Ultimate flexibility to access the industrial IoT and applied program data

- Disseminates the real-time edge computing feature to resolve problems related to the waiting time, cost, and security

- Safe, certified, and encrypted communication that can be expanded on the network topology

- Receives a library with more than 150 protocol adapters to access the data in real-time from the industrial equipment

- Thingworx Kepware Server can connect, manage, monitor, and control various automated systems and software application programs through one intuitive user interface

- Thingworx Kepware Server provided by Kepware is the best connection platform in the industry that uses a single intuitive user interface system for connection, management, monitoring, and control

- Thingworx Kepware Server uses the communication protocol based on OPC and IT to provide safe data

The Components and Features of Thingworx Kepware Server

1Thingworx Kepware Server

- Ultimate flexibility to access the industrial IoT and applied program data

- Disseminates the real-time edge computing feature to resolve problems related to the waiting time, cost, and security

- Safe, certified, and encrypted communication that can be expanded on the network topology

- Receives a library with more than 150 protocol adapters to access the data in real-time from the industrial equipment

- Thingworx Kepware Server can connect, manage, monitor, and control various automated systems and software application programs through one intuitive user interface

- Thingworx Kepware Server provided by Kepware is the best connection platform in the industry that uses a single intuitive user interface system for connection, management, monitoring, and control

- Thingworx Kepware Server uses the communication protocol based on OPC and IT to provide safe data

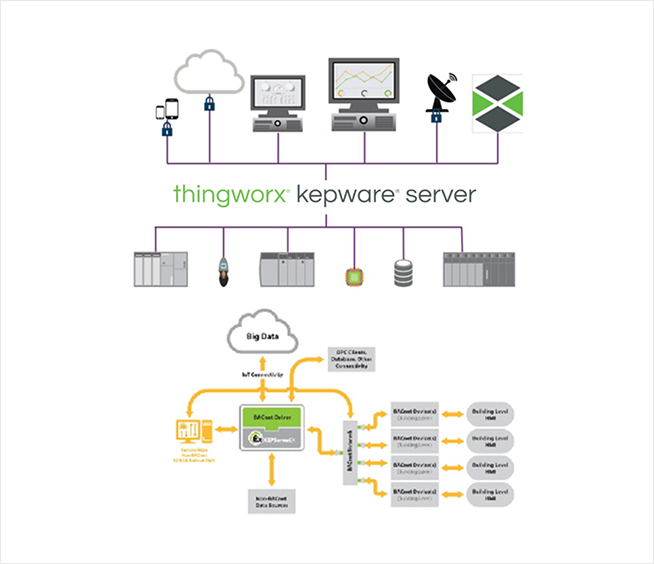

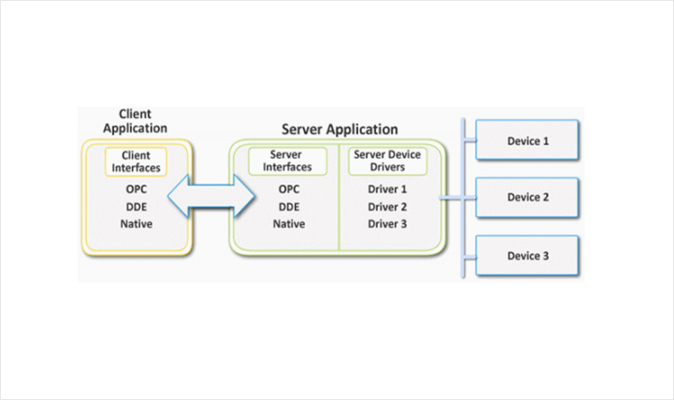

2Data Access

Thingworx Kepware Server provides data to OPC, exclusive protocol, IT protocol and general client application, and IoT and Big Data analysis software.

- Supports OPC UA (OPC Unified Architecture) specifications and OPC classical specifications, including data access (OPC DA), OPC alarm and event (OPC AE), and OPC HDA (Historical Data Access)

- Uses an automated interface to provide data to the major automated software, including iFIX of GE Intelligent Platforms (NIO) and InTouch (SuiteLink / FastDDE) of Wonderware

- Uses multilateral interfaces such as ODBC and SNMP to integrate with IT application programs. Communicates with the Splunk software and cloud services through the Industrial Data Forwarder of Splunk

- Exports record data and current data in the predefined speed if information needs to be accessed through a file or database

3Optimization of Communication

Reduces network and device load by controlling and reducing data, balancing user-defined load, and optimizing communication for each protocol.

- Defines the trouble-shooting standards of industrial ThingWorx devices

- Thingworx Kepware Server provides the tools to control communication frequency

- Thingworx Kepware Server tabulates the repeated commands of application programs

- Applied to Thingworx Kepware Server through remote programming using other clients’ application programs

4Connectivity Improved with Standardized Drivers

Thingworx Kepware Server supports a library of more than 150 drivers, which is the largest set of drivers in the market today

- The drivers establish connection to various OPC servers

- Supports remote instrumentation solutions

- Simulates data sources before dissemination for testing purposes

5Advanced Diagnosis

Thingworx Kepware Server provides real-time diagnosis and diagnosis of history for OPC events and communication.

- Provides real-time diagnosis and access to history for OPC events on servers

- Diagnosis of communication uses the embedded diagnosis tag for viewing and tracking on the OPC client application programs

- Provided through system definition tag and may be accessed by the same client that connects to the data source

KEPWARE

- KEPServerEX is the best connection platform in the industry providing a single source of automated industrial data for all areas of industry. Users can connect, manage, monitor, and control various automated devices and software application programs through a single intuitive user interface

- KEPServerEX provides various plug-ins, device drivers, and components suitable for most communication requirements

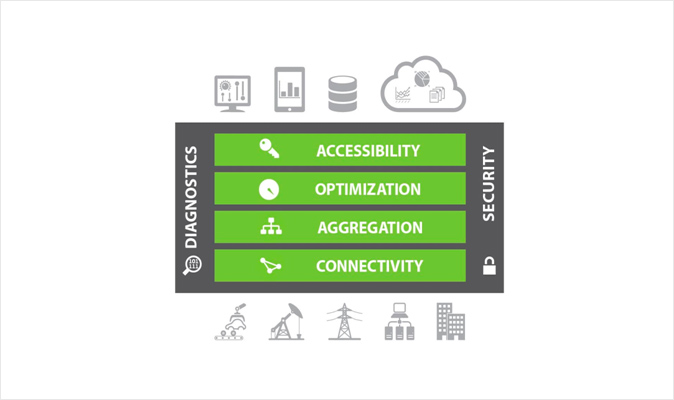

Accessibility

ThingWorx Kepware Server provides data to OPC, exclusive protocols, IT protocols and general client applications, IoT and Big Data analyzing software.

Optimization

Optimizes communication of devices through optimization of protocols and reduces network and device load.

Collectivity

Provides a single point to all information to simplify the configuration of application programs, so there is no need to purchase, operate, trouble-shoot, and maintain several solutions for individual connection.

Connectivity

Supports a wide variety of drivers to connect to various wired/wireless network media and database, user-defined software application programs, and other OPC servers.

Security

Includes various tools to control user access to the server and configure the security data tunnel.

Diagnosis

Provides OPC diagnosis to isolate the device and application program communication for trouble-shooting to access the real-time and past records of OPC events. Also diagnoses communication to capture the protocol frames transmitted between the server and all other devices.